Enclosed vs Open Frame 3D Printers

Are you torn between enclosed and open frame 3D printers? It’s important to know the good and bad of each. Qidi Tech Online Store explains why making the right choice matters.

When picking a 3D printer, think about your projects and where you’ll use it. The debate is about what each type offers.

This article will help you understand the differences. It aims to guide you in choosing the right 3D printer for you.

Key Takeaways

- Understand the fundamental differences between enclosed and open frame 3D printers.

- Learn about the advantages and disadvantages of each type.

- Discover the key factors to consider when choosing a 3D printer.

- Find out which type of 3D printer is best suited to your specific needs.

- Gain insights into the impact of enclosure on print quality and safety.

Understanding the Basics of 3D Printer Designs

To pick the right 3D printer, you must grasp the basics of their designs. There are mainly two types: enclosed and open frame. The main difference is in how they are built and work.

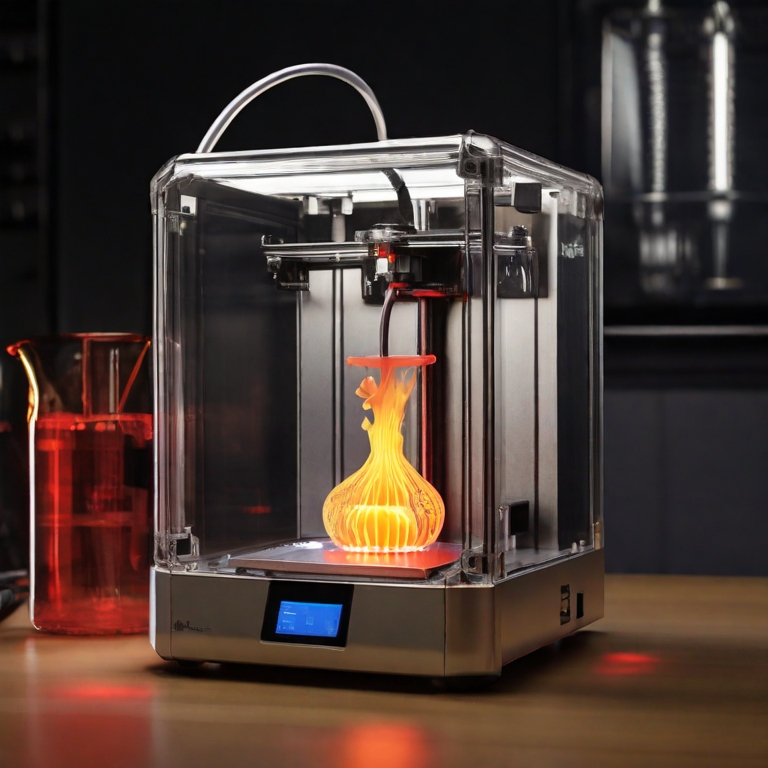

What Defines an Enclosed 3D Printer

An enclosed 3D printer has a fully enclosed print area. This setup keeps the temperature steady, which helps avoid warping and boosts print quality. These printers also have features like heated chambers and advanced air systems.

The key traits of enclosed 3D printers include:

- Temperature control: Keeps the temperature constant for better prints.

- Reduced warping: Lowers warping risk by controlling the print environment.

- Improved safety: The enclosed area makes it safer by shielding from moving parts and heat.

What Defines an Open Frame 3D Printer

Open frame 3D printers have an exposed build area without walls or doors. This design makes it easy to get to the print area. It’s great for watching and tweaking prints. But, it’s more open to temperature changes from the surroundings.

The main points of open frame 3D printers are:

- Ease of access: Makes it simple to check and tweak prints.

- Cost-effectiveness: They’re often cheaper than enclosed models because they’re simpler.

- Flexibility: It’s easy to change or improve open frame printers.

The Evolution of 3D Printer Designs

3D printing technology has grown a lot, thanks to better printer designs. Over time, printers have evolved into different types, like open frame and enclosed 3D printers.

Historical Development of Open Frame Printers

Open frame 3D printers were the first to appear in 3D printing’s early days. They were loved for being simple and affordable. The Lulzbot TAZ5 is a famous open frame printer that many people, both hobbyists and professionals, enjoyed using.

These printers were easy to get into, making it simple to watch and tweak prints. But, they were open to the environment, which could mess with print quality.

The Emergence of Enclosed 3D Printers

Enclosed 3D printers came along to fix some of the open frame’s problems. Printers like the Ultimaker created a controlled space that made prints better. This space kept the temperature steady, which helped avoid print warping and other temperature issues.

Enclosed printers were a big step towards better and more reliable printing. They were perfect for those needing top-notch prints for work or big projects.

Enclosed vs Open Frame 3D Printers: Core Differences

To choose the right 3D printer, it’s key to know the main differences between enclosed and open frame designs. These differences help you decide based on your needs and likes.

Structural Comparison

Enclosed 3D printers have a fully or partially closed chamber. This controlled space helps keep the print quality high by keeping the temperature steady and protecting against dust and drafts.

Open frame 3D printers, on the other hand, are open. This makes it easier to access the print area for bigger prints and manual adjustments. But, it might let in environmental factors that could harm the print quality.

Operational Distinctions

Enclosed and open frame 3D printers also differ in how they handle temperature and noise. Enclosed printers keep a steady temperature, which is good for printing with sensitive materials. They are also quieter because the enclosure absorbs some sound.

Open frame printers, being noisier, are more flexible for upgrades and changes. Their open design makes it easy to get to and tweak parts, appealing to hobbyists and DIY enthusiasts.

John Doe, a 3D printing expert, says, “Choosing between an enclosed and open frame 3D printer depends on your printing needs and how much control you want over the environment.” This shows why it’s important to think about your needs when picking a 3D printer type.

Print Quality Considerations

The debate between enclosed and open frame 3D printers often focuses on print quality. The design of a 3D printer greatly affects its ability to produce high-quality prints. We will look at the factors that impact print quality in both types of printers.

How Enclosures Affect Print Consistency

Enclosed 3D printers offer a controlled environment, leading to better print quality. The enclosure keeps the temperature stable, reducing warping and improving layer adhesion. It also protects against dust and drafts, which can harm print quality.

Enclosed printers also manage the cooling process better. This is key for materials that need quick cooling to solidify. By keeping the temperature consistent, enclosed printers ensure more consistent prints. They are great for complex geometries and detailed models.

Open Frame Print Quality Variables

Open frame 3D printers face more challenges due to environmental factors. Drafts, temperature changes, and dust can all affect print quality. But, with the right management, open frame printers can also produce high-quality prints.

To improve print quality in open frame printers, several steps can be taken. Place the printer in a draft-free area and use a draft shield or enclosure. Keeping the printing area clean is also important. Regular calibration and using quality filaments can further enhance print quality.

Material Compatibility Analysis

Choosing the right 3D printer means knowing which materials work best. The type of printer affects what you can print with. This choice is key to your project’s success.

Filament Types Best for Enclosed Printers

Enclosed 3D printers can handle many materials, even high-temperature ones. They’re great for printing with:

- High-Temperature Materials: ABS, Nylon, and Polycarbonate are top picks for enclosed printers. They can keep high temperatures.

- Specialty and Composite Filaments: These printers also work with special filaments. Think metal-infused or carbon fiber for extra strength.

High-Temperature Materials (ABS, Nylon, Polycarbonate)

ABS, Nylon, and Polycarbonate are favourites for enclosed 3D printers. They need a warm, controlled space to print well.

Specialty and Composite Filaments

Special filaments, like metal or carbon fiber, fit well with enclosed 3D printers. They bring special benefits like more strength and heat resistance.

Filament Types Suitable for Open Frame Printers

Open frame 3D printers can only handle a few materials. They’re best for low-temperature filaments.

- PLA and Other Low-Temperature Materials: PLA is a top pick for open frame printers. It prints at a low temperature.

- Limitations with Technical Materials: Open frame printers find it hard to work with technical materials. These need high temperatures or a controlled space.

PLA and Other Low-Temperature Materials

PLA is a favourite for open frame 3D printers. It’s easy to use and prints at a low temperature.

Limitations with Technical Materials

Printing with ABS and Nylon is tough in open frame printers. They lack temperature control and can warp.

Temperature Management and Control

Keeping the right temperature is key for top-notch 3D prints. This is true for both enclosed and open frame 3D printers. The temperature affects the print quality and how well different materials work.

Thermal Stability in Enclosed Environments

Enclosed 3D printers keep a steady temperature. This is important for printing with materials that don’t like changes in temperature. Thermal stability helps a lot when printing with ABS or Nylon, as they need a stable environment to print well.

| Material | Temperature Requirement | Print Quality Impact |

|---|---|---|

| ABS | Stable temperature above 60°C | High-quality prints with minimal warping |

| Nylon | Consistent temperature around 70°C | Strong, durable prints with reduced deformation |

Temperature Fluctuations in Open Frame Setups

Open frame 3D printers face more temperature changes. This can harm the print quality. Drafts or changes in room temperature can cause problems like layer adhesion issues or warping.

To reduce temperature changes, users can try a few things. Place the printer in a spot away from drafts. Or use an external enclosure to keep the temperature steady.

Environmental and Health Considerations

When choosing between enclosed and open frame 3D printers, think about the environment and your health. The right choice can affect both the planet and your well-being.

Emissions Control in Enclosed Printers

Enclosed 3D printers are better for controlling emissions. They come with filtration systems to catch harmful particles and fumes. This makes them safer for homes or places with little air flow.

Here are some benefits of using enclosed printers:

- Less exposure to harmful emissions

- Better air quality while printing

- More safety for users, mainly indoors

Ventilation Requirements for Open Frame Models

Open frame 3D printers need good ventilation to avoid health risks. Without a cover, they release harmful particles into the air. You need to ensure there’s enough air flow to keep these particles away.

| Ventilation Method | Description | Effectiveness |

|---|---|---|

| Natural Ventilation | Opening windows or using existing airflow | Moderate |

| Mechanical Ventilation | Using fans or exhaust systems to remove emissions | High |

| Fume Extraction Systems | Dedicated systems designed to capture emissions at the source | Very High |

Knowing what ventilation is needed for open frame printers helps keep your printing area safe.

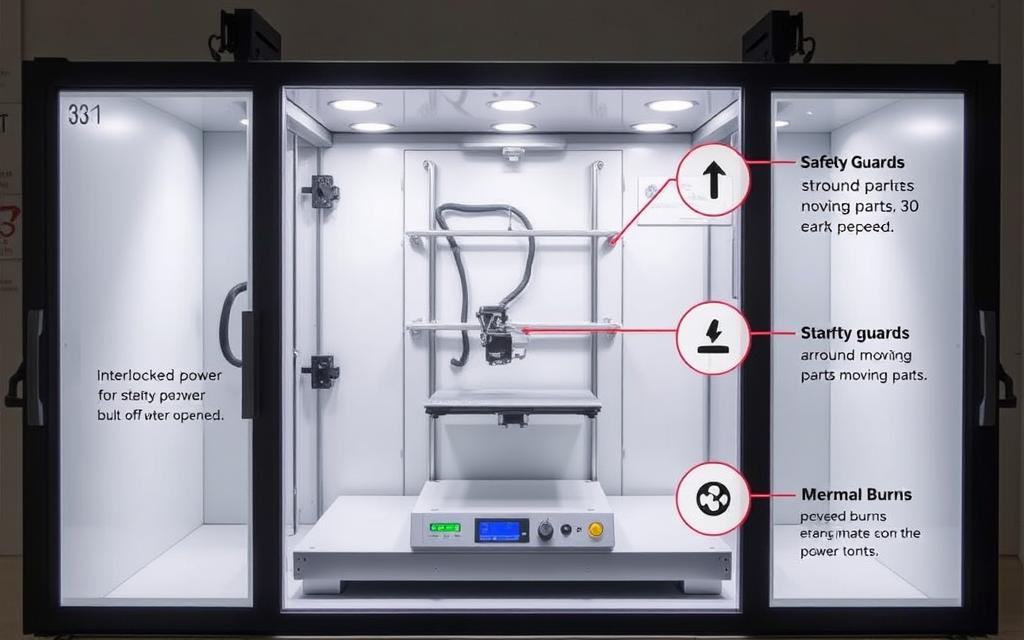

Safety Considerations for Both Designs

When you explore 3D printing, knowing about safety is key. The design of your 3D printer is vital for a safe printing space.

Enclosed Printers and Safety Features

Enclosed 3D printers focus on safety. They have a physical barrier to keep users safe from hot parts and moving parts. This makes them safer, great for homes with kids or pets.

These printers also have cool safety features. They can turn off automatically if there’s an error or blockage. Plus, they might have filtration systems to cut down on harmful emissions. These features help make printing safer and healthier.

Safety Challenges with Open Frame Printers

Open frame 3D printers are easy to see into and work on. But, they pose safety risks. Users might touch moving parts or hot surfaces, which can hurt them.

To stay safe, open frame printer users need to be careful. Keep the printer away from kids and pets. Also, always watch the printer when it’s on. Some people add DIY enclosures or safety screens for extra safety.

Choosing an enclosed or open frame 3D printer is important. Always follow safety rules and the maker’s advice. This way, you can enjoy safe printing.

Noise Levels and Workspace Disruption

The type of 3D printer you use can affect the noise level in your workspace. When deciding between an enclosed or open frame 3D printer, it’s essential to consider the noise levels each produces and how they might disrupt your work environment.

Acoustic Properties of Enclosed Printers

Enclosed 3D printers are generally quieter. Their design helps dampen both mechanical and fan noise. The enclosure acts as a soundproofing mechanism, reducing the overall noise emission. This makes enclosed printers a preferable choice for shared or quiet workspaces.

Key benefits of enclosed printers regarding noise reduction include:

- Reduced mechanical noise

- Lower fan noise due to controlled internal environment

- Overall quieter operation

Noise Emission from Open Frame Models

Open frame 3D printers, on the other hand, tend to be louder. They lack the sound dampening effect of an enclosure. The noise from the printer’s motors, fans, and other moving parts is more pronounced, potentially causing disruption in a quiet workspace.

Factors contributing to higher noise levels in open frame printers:

- Unrestricted mechanical noise

- Higher fan speeds due to lack of temperature control

- Potential for vibration and rattling

To illustrate the difference in noise levels between enclosed and open frame 3D printers, consider the following comparison:

| Printer Type | Average Noise Level (dB) | Noise Characteristics |

|---|---|---|

| Enclosed 3D Printer | 40-50 | Muffled, consistent hum |

| Open Frame 3D Printer | 60-70 | Loud, variable pitch |

In conclusion, if noise is a significant concern for your workspace, an enclosed 3D printer might be the more suitable choice due to its quieter operation. But, if you’re working in a well-ventilated area or have noise-cancelling measures in place, an open frame printer might be a viable option.

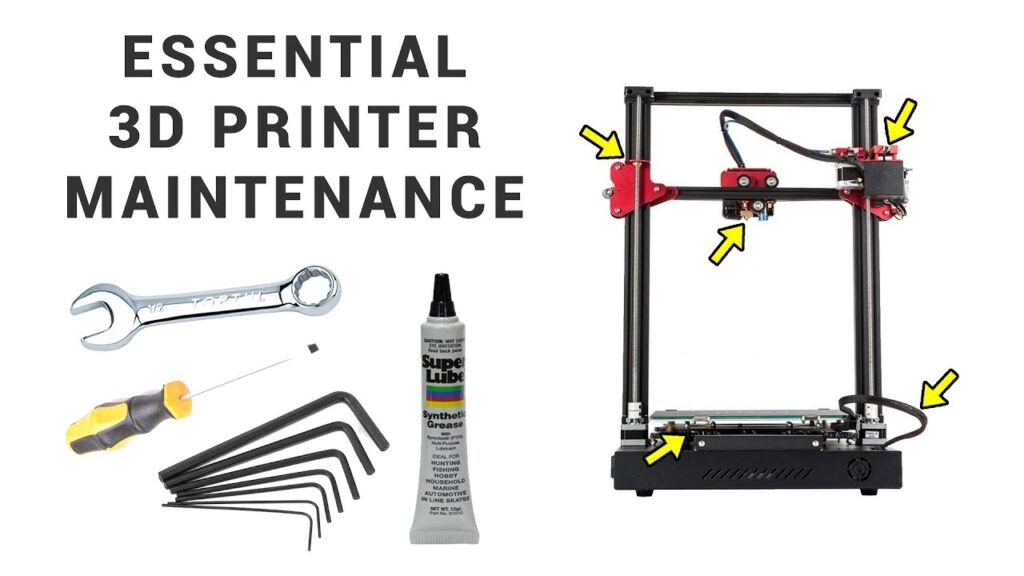

Maintenance and Accessibility Factors

The design of your 3D printer affects its maintenance and how easy it is to access. It’s key to think about how the design makes upkeep easier or harder.

Servicing Enclosed 3D Printers

Enclosed 3D printers improve print quality and control temperature well. But, they can be tricky to maintain. The cover makes it hard to get to parts inside.

You might have to take off panels to see and fix parts like the print bed or fans. Yet, many enclosed printers are made for easy upkeep. They have parts that are simple to remove and areas that are easy to get to.

To keep an enclosed 3D printer in good shape, do the following:

- Regularly check and clean the print bed and extruder.

- Look for and replace parts that are worn out, like nozzles or belts.

- Make sure the ventilation system in the enclosure works right.

Maintenance Ease with Open Frame Designs

Open frame 3D printers are easier to maintain because you can see everything. You can easily get to the print area, extruder, and other parts. This design makes it simpler to fix problems and do regular upkeep.

For open frame 3D printers, you should:

- Clean the print area often to stop debris from building up.

- Check the extruder and hotend often for wear.

- Oil moving parts to keep them running smoothly.

In summary, both enclosed and open frame 3D printers need upkeep. But, the design of the printer makes a big difference in how easy it is to maintain. Knowing this can help you pick the right 3D printer and keep it in top shape.

DIY Enclosure Options for Open Frame Printers

Adding a DIY enclosure to your open frame 3D printer can save money. Many users of open frame 3D printers, like the Lulzbot TAZ5, have made DIY enclosures. This has improved their printing experience.

Cost-Effective DIY Solutions

Building a DIY enclosure is cheaper than buying a commercial one. You can use materials like acrylic, wood, or aluminium. Here are some benefits:

- Cost Savings: Using recycled materials can cut costs.

- Customisation: You can design it to fit your printer and needs.

- Learning Experience: Making a DIY enclosure teaches you about 3D printer mechanics.

Performance Benefits of Custom Enclosures

A custom DIY enclosure can improve your printer’s performance. Here are some benefits:

- Improved Temperature Control: Enclosures keep the temperature stable, important for some materials.

- Enhanced Print Quality: They reduce drafts and keep the environment consistent, improving print quality.

- Increased Safety: Enclosures contain hazards like hot ends and electrical parts, making printing safer.

Choosing a DIY enclosure lets you design it for your needs. This can lead to better results than an open frame setup.

Ideal User Profiles: Who Should Choose Each Type

Choosing the right 3D printer depends on your needs and where you work. You should think about the materials you use, the quality you want, and your workspace. This helps decide between an enclosed or open frame 3D printer.

Best Scenarios for Enclosed Printer Adoption

Enclosed 3D printers are great for advanced materials that need careful temperature control. This includes high-temperature filaments and moisture-sensitive materials. If you want high surface quality and dimensional accuracy, an enclosed printer is best.

Experts say, “enclosed 3D printers give better print consistency and less warping. This is because they keep a stable internal environment.”

“Enclosed 3D printing environments significantly enhance the quality of prints by minimising the impact of external factors such as drafts and temperature fluctuations.”

When Open Frame Printers Make More Sense

Open frame 3D printers are perfect for those who need flexibility and ease of access while printing. If you often need to adjust or check your prints, the open design is better. They are also cheaper and great for beginners.

Experts say, “open frame 3D printers are versatile. They are good for many uses, from hobby projects to education.”

Top Recommended Enclosed and Open Frame Models

Both enclosed and open frame 3D printers have their own benefits. It’s key to look at the top models in each category when picking a 3D printer. This helps you understand their features and advantages.

Premium Enclosed Printers

Enclosed 3D printers keep the printing area controlled. This is great for using certain materials and getting top-quality prints. Here are some of the best enclosed models:

- The Bambu Lab X1C, known for its advanced features and high-speed printing.

- The Creality Enclosed 3D Printer, which is compact and fully enclosed.

| Model | Key Features | Print Quality |

|---|---|---|

| Bambu Lab X1C | High-speed printing, advanced features | High-resolution prints |

| Creality Enclosed | Compact, fully enclosed | Consistent print quality |

Leading Open Frame Options

Open frame 3D printers are loved for their flexibility and simplicity. Here are some top models:

- The Creality Ender-3 V2, praised for its affordability and large build volume.

- The Prusa i3, known for its high-quality prints and large community support.

When choosing a 3D printer, think about what you need for your projects. The recommended 3D printers listed above are among the best. They offer a variety of features and capabilities.

Understanding the benefits of enclosed 3D printers and open frame 3D printers helps you make the right choice. This ensures your 3D printing needs are met.

Conclusion: Making Your Decision

Choosing between enclosed and open frame 3D printers depends on your needs, budget, and how you plan to use it. This guide helps you understand the main differences. This way, you can make a choice that fits your needs.

Enclosed 3D printers keep temperatures stable, reduce harmful fumes, and are safer. Open frame printers are easier to work on, cheaper, and more flexible. Think about your projects, materials, and workspace when deciding.

By looking at the points in this guide, you can pick the best 3D printer for you. Whether you want the best print quality, safety, or flexibility, the right choice depends on your specific situation.